Although there had previously been alternatives to agricultural work in Adderbury, notably with plush weaving, which involved some 34 inhabitants in 1841 (see Taylor, 1964), the first activity that could be properly called “industrial” in the village came with the quarrying of ironstone in the late nineteenth and early twentieth centuries. This took place along the present-day Aynho and Oxford Roads to the east and south of the village centre respectively.

In contrast to the earlier Aynho Road quarries, those along the Oxford Road had relatively easy access to transport, and the infrastructure developed in the early days for the ironstone workings encouraged a succession of activities with new uses taking over from old over a long period of time. And, although they were not the earliest ironstone quarries in Adderbury, the pits around the Oxford Road would have made the greatest impact on the countryside, transforming it into an industrial landscape, with tramways, tunnels and steam locomotives to be seen on all sides from the main road entering Adderbury from the south.

Banbury and Cheltenham Direct Railway

The major objective of the railway was to enable the North Oxfordshire ironstone quarries to communicate directly with the South Wales iron foundries, but it took many years from the start of work in 1875 for this to be possible. Adderbury station opened on the same day as the railway as a whole: April 6th, 1887. What remains of the station is best viewed from the entrance to the present Station Yard Industrial Estate. The main line followed the line of the present units; it was dualled to this point but resumed single track operation as it continued west beneath the Oxford Road.

The station at Adderbury was very similar in layout to the stations at King’s Sutton and Bloxham. It had two facing platforms, with the main station buildings on the north side, with only a shelter on the other side. The two platforms were connected by a “barrow crossing”. From the industrial point of view, however, the most important feature at Adderbury were the private sidings to the south of the main line. These were used in turn by every significant industrial concern in this part of Adderbury, beginning with the ironstone quarries and only ending with J. Bibby Agriculture, who continued to use them until 1969.

The BCDR company did not operate services on the line: it contracted the Great Western Railway to do so in return for a share of the receipts and, indeed, the GWR bought the railway in 1896. Ironstone traffic, local haulage (including coal for the gasworks) and passenger traffic, remained the bread and butter business of the line, although it was also unofficially known as the “ports to ports” line, served by an express which, in an eleven hour daily journey, linked the North East to the South Wales coast and provided the basis for many day excursions to Barry Island from Adderbury, particularly those funded by the village Friendly Societies.

Adderbury Ironstone Quarries

The Geological Survey for Oxfordshire was started in 1857, the resultant maps being published in 1860. These highlighted the fact that just below the surface of the fields in north Oxfordshire there lay vast quantities of ironstone – in some places this could be as much as 30,000 tons per acre. It is possible to extract the iron from ironstone, and mining companies were not slow to seek to exploit this. The Hook Norton Ironstone Partnership obtained leases to work ironstone on the south side of Adderbury Station in the late 1880s. “At Bloxham and Hook Norton there is a very rich bed of iron ore, which has been purchased by the Oxfordshire Ironstone Company, and a very large income is expected to be derived from this source over the Banbury and Cheltenham Railway”, reported the Banbury Guardian on 1st September, 1884.

The area occupied by the present Twyford Mill industrial estate provided the hub of the transport links between the quarry sites to the south and west and the railways sidings to the north.

Operations began in 1890 and the Partnership purchased a one foot eight inch gauge 0-4-0 Manning Wardle locomotive, Florence, from the Florence Colliery in Staffordshire. A tramway was built on which Florence could be used. This ran south from a tipping dock in Adderbury Station goods yard, initially on a gradient of 1 in 17, then passed under the bridleway to Paper Mill Cottages to reach the working face next to the Oxford Road. Company offices and locomotive shed were located at the top of the initial incline. Problems were experienced with locomotive operation and the incline was changed to cable haulage powered by a stationary steam engine. The subsequent, flatter route southwards to the quarries was horse-worked. Florence was eventually transferred to the Partnership’s quarries at Hook Norton. A further face was later opened closer to Adderbury Grounds Farm.

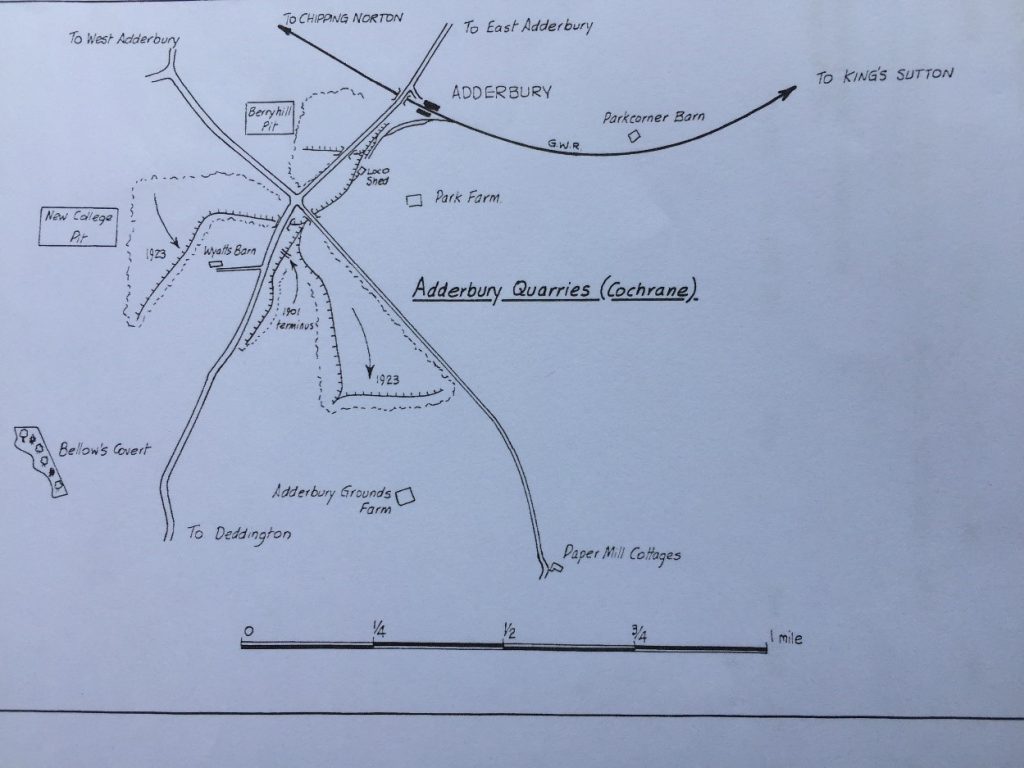

The Adderbury properties of the Hook Norton Ironstone Partnership, which went into liquidation in 1903, were taken over by Cochrane & Co (Woodside) Ltd. in about 1906 and were worked by them until 1922. They opened two further pits, both on the west side of the Oxford Road, Berryhill Pit, which was opened in the early 1900s and New College Pit, further to the south west. These had an even more complex route to the all-important sidings at Adderbury Station. The Berry Hill pit accessed the railway via a funicular under the Oxford Road itself, and the New College pit joined this via a tunnel. The full extent of the workings is shown in the map below, taken from Tonks (1988) (p.46).

The work was hard and the pay relatively low. An idea of the rates is taken from the nearby Astrop quarries, where four old pennies per ton for wet ore and threepence halfpenny for dry ore was paid, with twenty tons per day being the average output per man. Three pence per yard was paid for removing the earth and an extra farthing for tipping waggons. Nonetheless, mining work was popular in early twentieth-century Adderbury. There were 34 Ironstone workers listed in the 1901 census, and Cochrane & Co had 78 men at the beginning of the First World War. This was when the quarries were at their busiest, and when the shortage of iron became acute after 1916, men working in the ironstone quarries were eventually granted exemption from war service.

“By August [1917] some of the Adderbury ironstone workers had been sent home from the trenches to resume work in the ironstone quarries. Clearly there was a great need for iron and steel and as the war continued ironstone workers became exempt from call-up. The shortage of such workers in the area meant that men from other areas came to the village as lodgers. A number came from Cornwall (possibly tin miners) to work on the local ironstone.” (Davis 2014, p. 77).

Cochrane’s plants at Woodside and Adderbury were put up for sale in 1924, but hopes that the quarries might be re-opened under new ownership were dashed by the 1926 General Strike. Little remains to be seen of the mining activities of a hundred years ago except that the surface of the fields to the west of the Oxford Road in this area are much lower than we would expect from the level of the hedges and surrounding roads and tracks, indicating that the fields have been backfilled after extraction of quantities of ironstone.

In the late 1950s a proposal was made to carry out open-cast mining to a depth of about 30 feet in this part of Adderbury, south to Deddington and west to Hook Norton. After the ore had been removed the top-soil would have been replaced and the land ‘re-instated’, but with the fields lowered and hedges standing proud on sharp embankments. The open-cast mining was due to last for 30 years or so. Two public enquiries eventually led to the rejection of the proposal. The full story can be read at deddingtonhistory.uk/photos,filmsandillustrations/ironstone.

The Duffield Iron Corporation Ltd

The Corporation used a tractor to bring ore from the quarries to the west of the Oxford Road, using the existing funicular railway track. A furnace was erected and by Friday, 25th July 1930, the Corporation was reporting that “the retort furnace was lighted for the first trial on Monday morning last and continued until Tuesday evening. Our engineers are entirely satisfied with the heat conditions.”

Reports throughout the 1930s refer to the expansion of the site and to negotiations to sell rights to the process to concerns abroad, particularly in Ireland, Italy, Australia and New Zealand. A report in December 1938 spoke of the intention to start smelting 150,000 tons of ore a year “early in the New Year”, although Tonks (1988, p.45) says only that “the plant continued to operate in a small way up to the outbreak of war”. In 1939 a delegation visited on behalf of the Iron and Steel Controller as a result of a request by the Duffield Corporation to the Ministry of Supply to recognise their work as part of the war effort. Unfortunately for the company, the report was not in their favour and the site was instead requisitioned by the Ministry, and much of the factory was dismantled.

By the time the Corporation could report again in 1945, Mr Duffield said that it had taken “17 years to show, by a series of adaptations of plant design and method, the metallurgical practicability of direct reduction of iron ore”. The other directors, however, emphasize that “it has yet to be tested on a sufficiently large scale to ascertain its value commercially” and say that research into the process had ceased. F. Lindley Duffield died in Sydney, Australia, on July 22nd, 1949.

A group of Duffield Iron Works employees

Ministry of Aircraft/Northern Aluminium

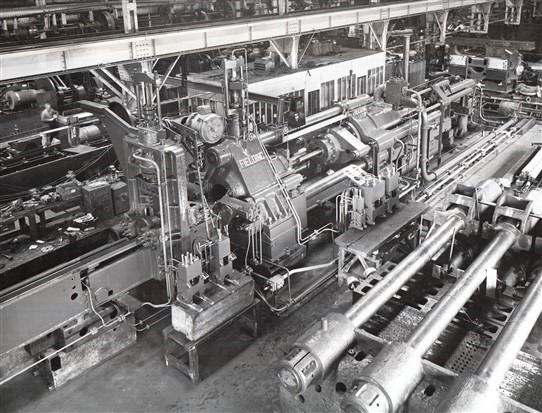

The Duffield site was hence taken over in 1939 by the Ministry of Aircraft. The war work at Adderbury was carried out as a subfactory of the Northern Aluminium (later Alcan/Alcoa) plant at Southam Road in Banbury. Northern Aluminium Company built and operated a major recycling plant here to process aluminium from both British and German aircraft crashes. The need for aircraft put huge demands on the aluminium industry as production of aircraft rose from 2,828 units in 1938 to 15,049 in 1940 and over 26,000 by 1944.

According to Potts’ A History of Banbury, in Adderbury and at the Southam Road plant in Banbury, a strong alloy for aircraft skins was made and frames and wing spans were extruded. Thousands of wing spans were made for the famous Lancaster bomber. The workforce at Adderbury and Banbury combined rose to a peak of 2300. Women constituted half the workforce, doing work previously considered quite unsuitable. Many shot-down aircraft, German and British, were dumped at Adderbury and re-processed, at one period to the extent of 50 tons per month. Large sections were produced for the famous Bailey Bridges, and aluminium powder for flares and incendiaries and landing strips for emergency airports were also produced.

The Lancaster bomber

Some crashed planes came by rail and others were trucked to the factory in ‘Queen Marys’, which were 60ft long low loader trucks specially built for transporting aircraft. A yellow nosed, Me 109 with bullet holes across its fin, body and wing, was placed at the front gate of the factory for several weeks for all to see. Bert Lane was once Stationmaster for Adderbury; he recalled the sight of frames of wrecked aircraft, axis and allied, jammed into railway waggons on the siding.

Twyford Seeds/Bibbys

After a fire at the original Twyford Mill, on the Cherwell near Twyford Wharf, the Oxford Road site was taken over in 1946 by Twyford Seeds, which had been founded in 1936. In a move which still causes confusion today, Twyfords brought the “Twyford Mill” name with them from their original home. Twyford Seeds were one of the country’s leading plant breeding establishments, with an arable farm at Walton Grounds for seed breeding and multiplication and a pedigree seed farm at Cottisford. There was a plant breeding department in the former walled garden of Adderbury House.

Twyford Seeds was acquired in 1952 by what would eventually be known as the Feeds and Seeds division of J. Bibby & Sons Ltd. There were already strong connections between the companies, since Bibby’s had acted as selling agents for Twyford products in some areas and it was intended to merge the sales staff of the two companies. Bibbys, however, were careful to keep the use of the Twyford name for premium products, and continued to recruit scientific staff to Twyford Seeds, rather than to Bibby’s, throughout.

Bibbys established a seed mill on the site, since another reason for the acquisition was a wish to replace their original feed mill at Liverpool by a series of mills in different parts of the country. Adderbury was Bibby’s first true ‘country’ mill, and over the years was a very successful location for the firm. A small feed plant was built on the site to manufacture pig and poultry feeds under the Bibby brand. In 1968-9 Bibby’s closed its mill in Wandsworth and re-allocated some of its tonnage to Adderbury. In 1970 Bibby’s seed cleaning plant at Colsterworth closed and its business also transferred to Adderbury. In 1973 the Adderbury mill was badly damaged by fire, but was re-equipped and brought back into production by 1974. The Headquarters of the Feeds and Seeds division of Bibbys moved to Adderbury in 1976. The Division was the largest in the company, with a workforce at the end of 1977 of 1150 nationally.

Fired Earth

Fired Earth (a literal English translation of the Italian “terracotta”) began trading in 1983 from a lean-to on the side of a farmhouse in Middle Aston. Its range of floor tiles soon expanded to wall tiles and by 1990 it had outgrown its premises and Fired Earth became the new owners of Twyford Mill Estate. According to Nicholas Kneale, the founder, “Bibby found it could fulfil its needs on a smaller site. We refurbished a large building into a showroom, warehouse and offices.”

The firm continued to grow, with paint and wallpaper, bathrooms and kitchens being added to the range. By the mid-1990s Fired Earth had 15 showrooms across the country, with the first London showroom being added in 1996. Fired Earth was taken over by Silverfleet Capital in 1998, and then sold on to Agafood Services plc, who were looking to increase their retail activities. They now have an AGA showroom within the Fired Earth building.

The Site Today

The Twyford Mill site currently houses a range of commercial, service industry, educational and light engineering ventures, with the transition in little more than a century from mineral extraction and heavy engineering closely reflecting changes in the UK economy as a whole. At the same time, the industrial park framework both here and at the neighbouring Station Yard has kept intact the outlines of the infrastructure of Adderbury’s early industries.

Phil Mansell

2020

References:

Bibby, J.B. & C.L.Bibby (1978): A Miller’s Tale. A History of J.Bibby and Sons Ltd, Liverpool. J.Bibby and Sons Ltd.

Davis, B. (2014): In It Together, Adderbury at War. Robert Boyd Publications.

Potts, W.(1958): A History of Banbury. Banbury Guardian Offices.

Taylor, A.M. (1964): Gilletts. Bankers at Banbury and Oxford. Oxford, at the Clarendon Press.

Tonks, E. (1988): The Ironstone Quarries of the Midlands: History, Operation and Railways. Part II. The Oxfordshire Field. Runpast Publishing, Cheltenham